FR/ARC Protective Outerwear

Extensive Product Testing

| WATERPROOFNESS: Next, full garment prototypes are sent to W.L. Gore where they are vigorously rain shower tested to storm conditions. The rain shower test exposes garments to a wide range of simulated rain conditions from moderate to extreme, vertical, and wind driven, while rotating the mannequin which is equipped with sensors to detect leakage. Should any leaks be detected, the design is either rejected or requires modification to correct performance before re-testing. Additionally, Lac-Mac regularly tests products internally using a Hydrostatic Head Tester. This test for waterproofness, applies water under pressure to vulnerable points such as seams to ensure they are liquid-proof, with no leaks.

|

|

DURABILITY:

All Gore fabrics are tested for resistance to abrasion. The outer fabric layer must be able to withstand the rugged day-to-day conditions the garment will be exposed to. The Martindale Abrasion Tester rubs the fabric repeatedly against a rough surface with considerable pressure. Each rub (cycle) simulates 12 hours of actual wear. We performed abrasion testing on GORE-TEX PYRAD® to beyond 20,000 cycles with no breakdown of the face fabric. 20,000 cycles represents approximately 240,000 hours of wear, with minimal surface abrasion evident and the barrier membrane uncompromised.

BREATHABILITY:

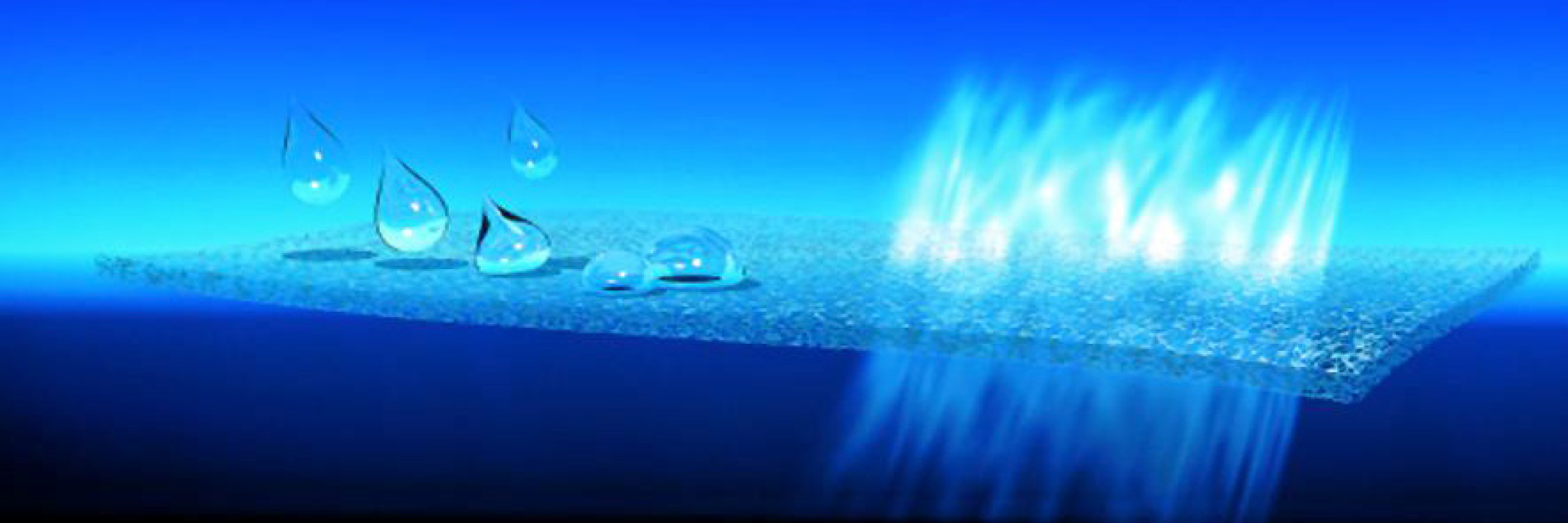

GORE® fabrics, which are engineered to be both waterproof and breathable at the same time begins with a GORE® membrane. The membrane is the heart of all GORE® products. It contains over 9 billion microscopic pores which are approximately 20,000 times smaller than a drop of water, but 700 times bigger than a water molecule making the membrane completely waterproof from the outside, while allowing perspiration to escape from the inside. The industry accepted method for measuring breathability is test method ASTM E96 which measures values of water vapor transfer through materials over a 24 hour period.

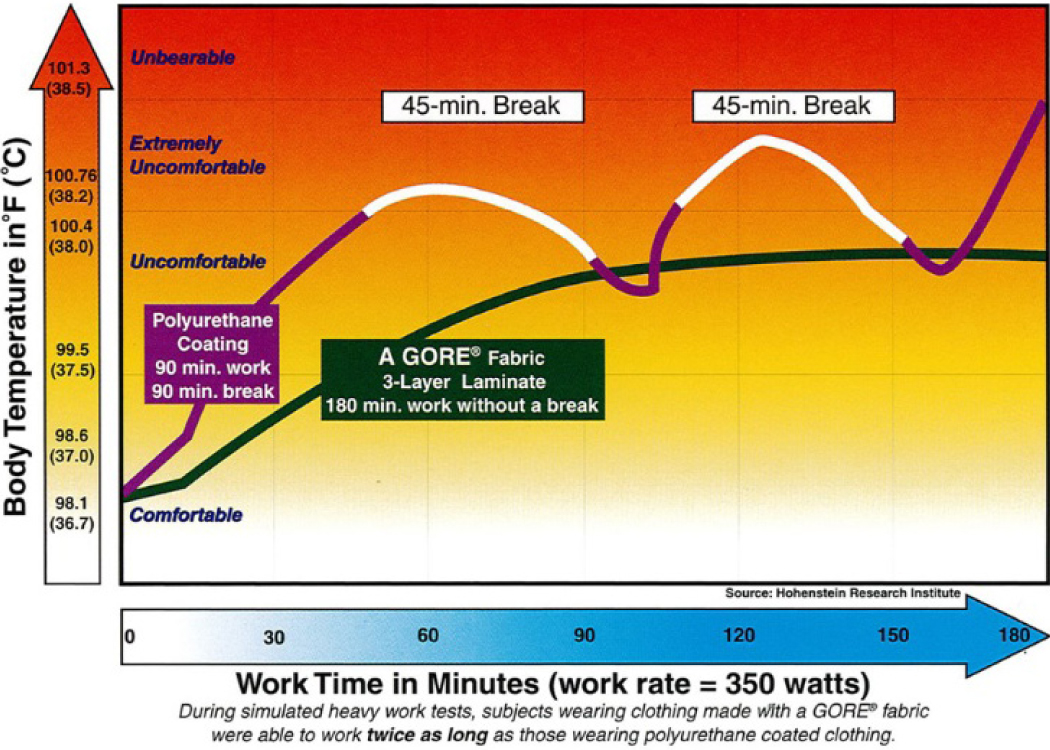

| COMFORT: |

|

HIGH-VISIBILITY:

Garments made using compliant high-visibility fabrics significantly aid in workers safety by ensuring the wearer can be seen under both day and night conditions. Lac-Mac’s FR ARC-Flash outerwear has been 3rd party tested, and our High-Visibility Yellow as well as our High-Visibility Orange meets both the CSA Z96 Standard as well as the more stringent U.S. Standard ANSI/ISEA 107. Products which do not meet a high-visibility standard are not providing workers with adequate visibility during daylight and low light environments. Visibility during night conditions is supported by retro-reflective markings which are applied to both the Jacket as well as the Pant and Overall. Lac-Mac uses only 3M Scotchlite™ Reflective FR Tape which offers the best in reflective performance for the life of the garment.

|

| WEAR TRIALS: |

Download Extensive Product Testing Pages in PDF Format

Extensive Product Testing To Ensure Maximum Performance PDF …

-

Wear Trial Request

LAC-MAC offers a comprehensive wear trial program allowing your company to do its own testing and evaluation of our FR/ARC Protective Outerwear Garments. You must complete the Wear Trial Request Form to be eligible.

LEARN MORE -

for more information about our

FR/ARC Protective Outerwear

click here to contact our sales teamNeed More Information?

For more information about our FR/ARC Protective Outerwear click here to contact our sales team.

Learn More